Electric Drum Brake - Troubleshooting Guide

Step 1. Electric vs Mechanical issue?

Determine whether the problem is an electrical problem or a mechanical problem.

Handbrake Fitted:

Start by applying the handbrake to check if the brakes have applied evenly and correctly.

Handbrake Not Fitted:

Adjust the drums till they are dragging and see if they all generate an even drag on each wheel/hub.

If all drums produce the same degree of braking drag, the problem is not mechanical but electrical. If the drums do not produce all the same amount of drag when adjusted, then there is a mechanical problem.

Possible Mechanical Problems:

- Ingress of a foreign matter causing shoes to slide rather than grip. Eg grease or paint

- Shoes/Pads are worn out

- Inner drum assembly is not functioning correctly - broken or damaged components?

Remove the drum/s that are under-performing to evaluate and repair.

Possible Electrical Problems:

- Damaged/exposed wiring

- Shorted electro-magnet (taking power from whole system causing other drums in the setup not to function)

- Open circuit on electro-magnet (will cause a drum to not brake while the others do)

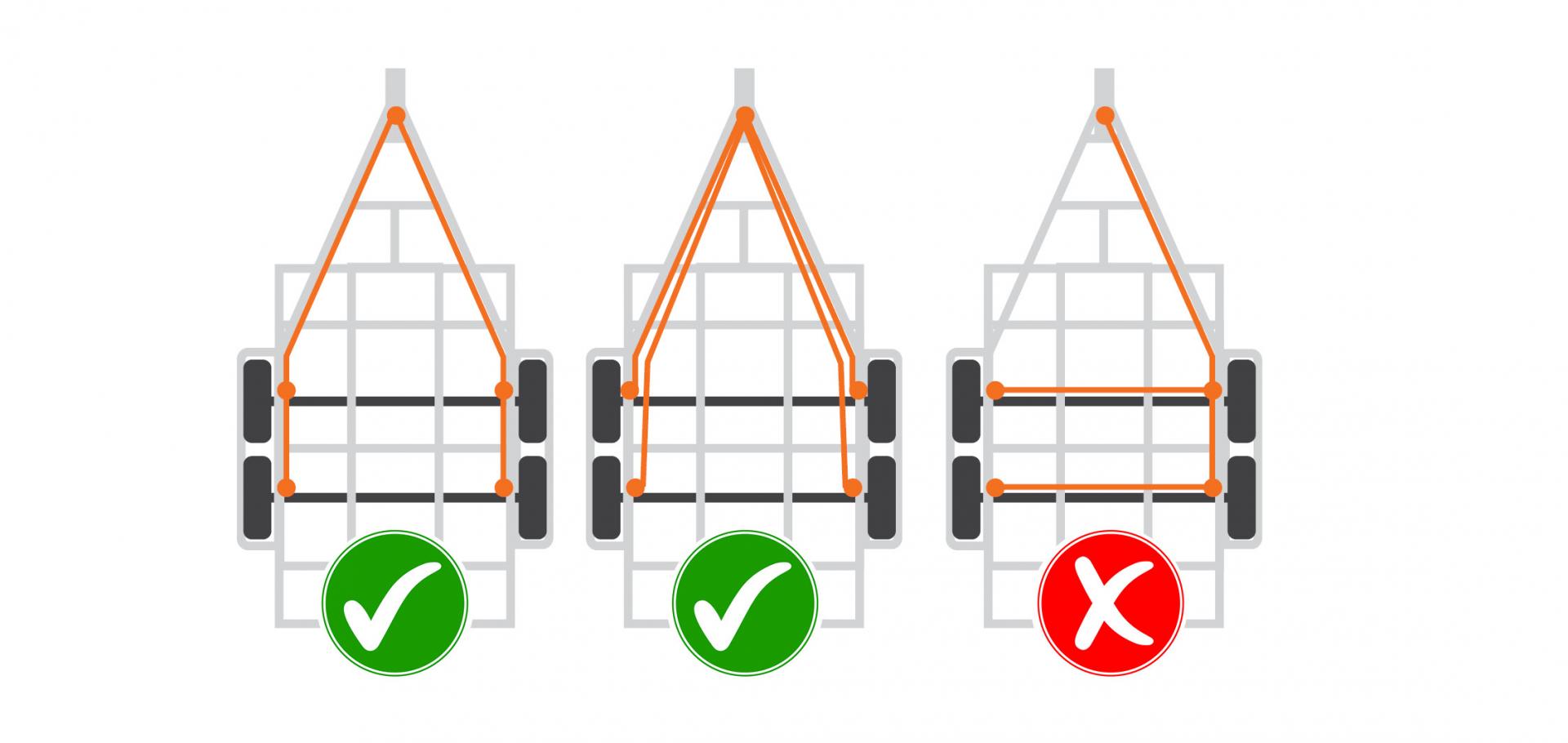

- Poor wiring layout – Electric drums work best when all wiring from coupling to hub is equal length (see diagram below).

- 2 axles = 0.8ohms

- 1 axle = 1.6ohms

- 1 magnet = 3.2ohms

Before removing drums due to electrical problems, test the resistance of the magnets. Below are approximate resistance values.

Above values are approximate and could vary up to +/- 5%.

If readings are not close to the above, disconnect drum wiring and individually check each drum. Inspect and check wiring condition as an open circuit or exposed wire could be shorting the system.