Introducing: Forged U-Bolts

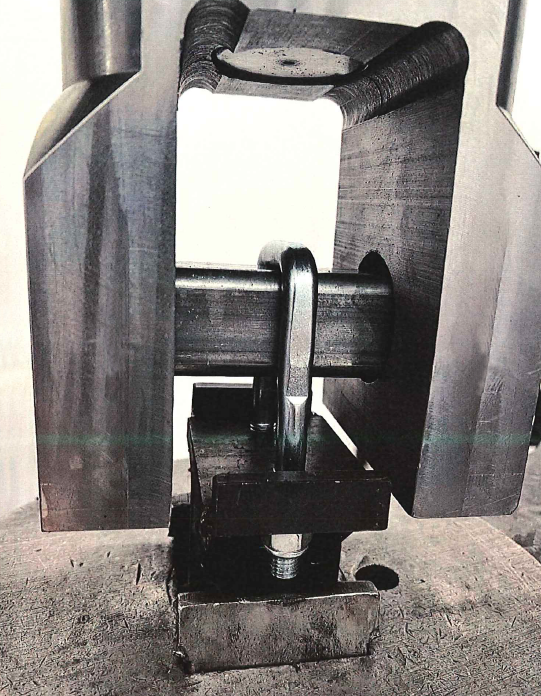

The connection between axle and spring is a very critical connection, if there is a failure in this connection it can lead to catastrophic failure. That is why we’ve designed the range of forged u-bolts so that you can be assured that it will cope with demands of the harsh environment.

Why Forged?

- The benefits of forging mean we can shape the U-bolt, increasing contact area to better fit the contour of the axle. We incorporate a flat edge along the top of the U-bolt to optimise the load distribution across them and give a perfect fit on Trailparts tube axle (SHS).

- The process of hot forging means the U-bolt shape is formed while the metal is red hot. This means the metal flows naturally on the bends into shape ensuring structural integrity of the part.

- These U-bolts have been through a rigorous materials testing process, the test units were capable of withstanding the equivalent of a 14ton load!

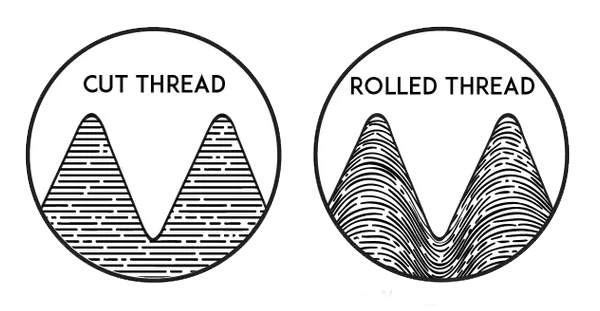

- New rolled threads for 30% increased strength and accuracy.

- Each U-bolt is batch numbered for quality assurance.

- Hot Dip Galvanized for maximum corrosion resistance with a powder coat finish not only looks good but also makes inspection easy.