Unihub: Trailparts Revolutionising Trailer Hubs

Unihub is redefining the standards of trailer axle performance with its innovative design, offering unmatched durability, reliability, and versatility. It has been engineered in New Zealand for Australasian roads, which are unfortunately worlds apart from the sealed, broad highways of Europe and USA.

- They are a great market fit – The Unihub range was designed around universally available, low-cost trailer wheels. Trailers imported from Europe with similar bearing technology use expensive difficult-to-obtain trailer wheels likely to leave a trailer stranded if a wheel becomes damaged.

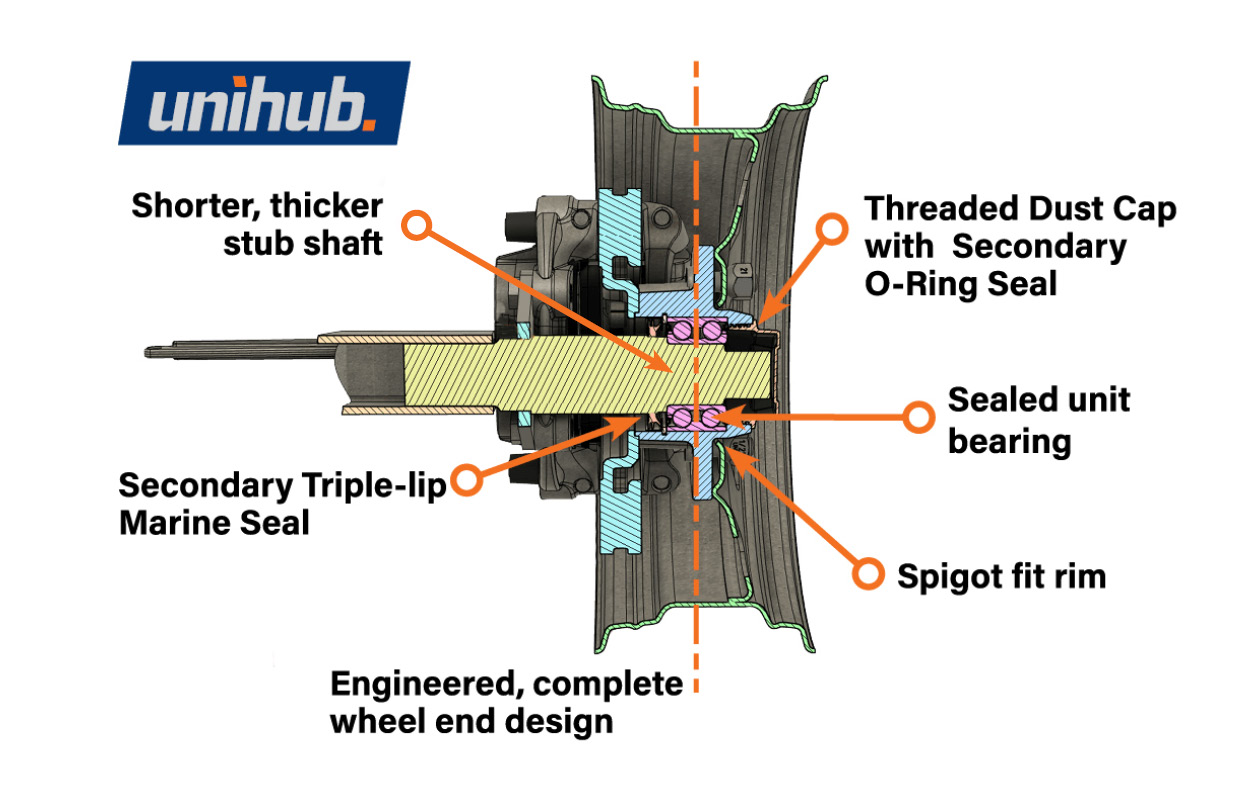

- They are well engineered – Unihub gave us an opportunity to re-engineer the whole wheel-end design so that it could safely carry rated loads with a wide safety margin. Prior to Unihub being released, trailer axles mostly used components carried forward from early 1970’s Holdens and Fords manufactured in Australia and mated them with trailer wheels they weren’t designed to be used with – leading to loads being introduced they weren’t designed for. The Unihub design applies load through the centre of the bearing, axle, and wheel.

- They are reliable and low maintenance – Trailers using Unihub axles do not require axle maintenance, unlike taper-roller fitted axles which require bearing adjustment and re greasing regularly. And the wide safety margins gained with Unihub means components are less stressed, and less prone to fatigue induced failure in otherwise harsh conditions.

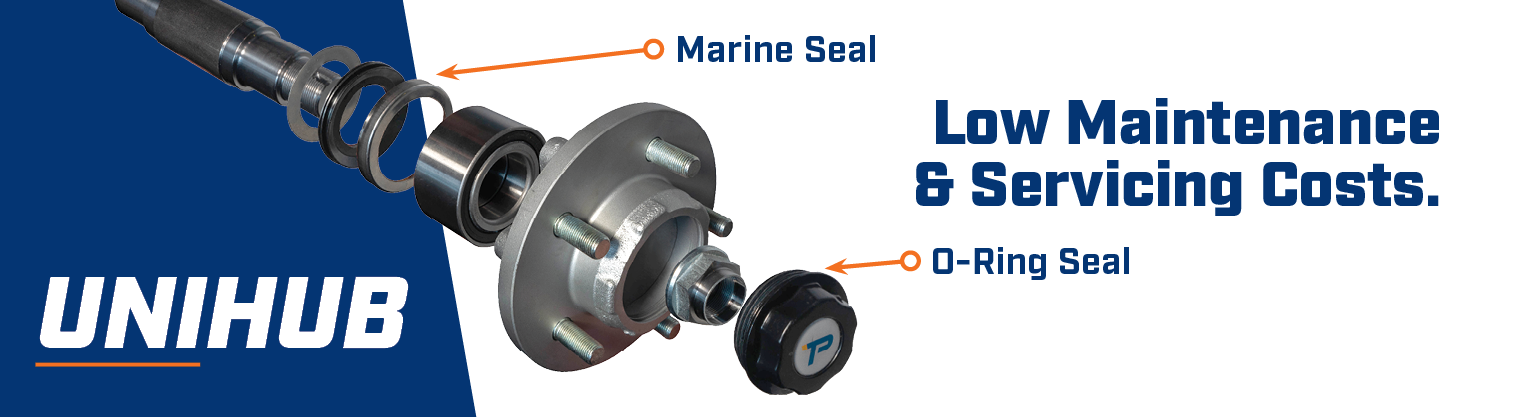

- Bearings are doubly protected – During the engineering process, we took the opportunity to create a dual-seal arrangement on both sides of the hub. Although the bearings themselves have seals used on cars without extra sealing, our knowledge of how trailers are really used led us to introduce an all-new marine-grade seal on the inner, and to develop a screw-in grease cap with O-ring seal on the outer. These keep dust, dirt and water out of the bearing, further enhancing their life.

- They are easy to fit – Trailparts understands the importance of user convenience, and Unihub reflects this philosophy. Installation is an easy process that removes many of the variables and specialist knowledge that installing taper roller bearings require.

Here’s what experienced trailer builders and users are saying about Unihub.

These features exemplify the Trailparts' approach to quality and innovation. Unihub will improve installation times for trailer builders whilst giving a sound business case for change from the status quo, while providing a quantum improvement in performance and reliability for the trailer user.

You can trust Unihub to be the heart of your trailer. Commercial and fleet users will appreciate the difference it makes to maintenance costs and fleet availability, and those on recreational towing adventures will appreciate the peace of mind with Unihub.

UNITISED BEARING

Trailparts have specified the unit bearings best suited for Unihub, which in both ratings are back-to-back duplex designs with integrated seals. These feature super-finished bearing raceways and a lower coefficient of friction in operation, in turn generating less heat and leads to longer life. Bearings are also preloaded at manufacture, which means the chance of an installer causing damage through over-tightening is eliminated.

Both variants we use are a sealed-for-life design that doesn't require any maintenance. When used on Trailparts assembled axles, in conjunction with the secondary seals being fitted, carry a 3 year warranty - another NZ trailer industry first.

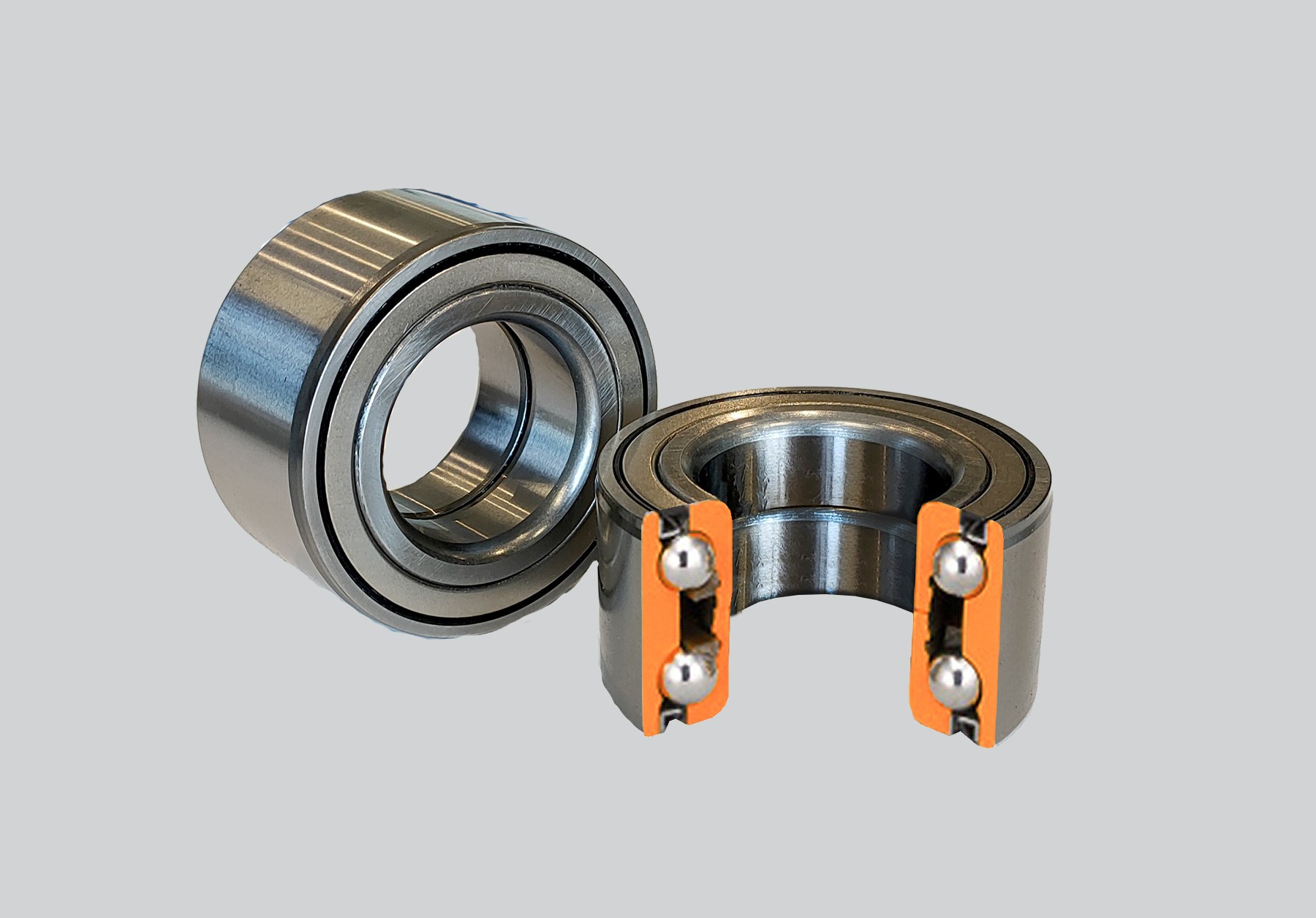

Dual row angular contact bearings - 1800kg

These use spherical ball bearings, and the design of the races angle the load towards the bearing centre line. These can bear radial and axial loads from all directions about the hub. They can also bear tilting effects, so withstand the twisting loads that non-steering wheels in sets see (tandem trailers, for example).

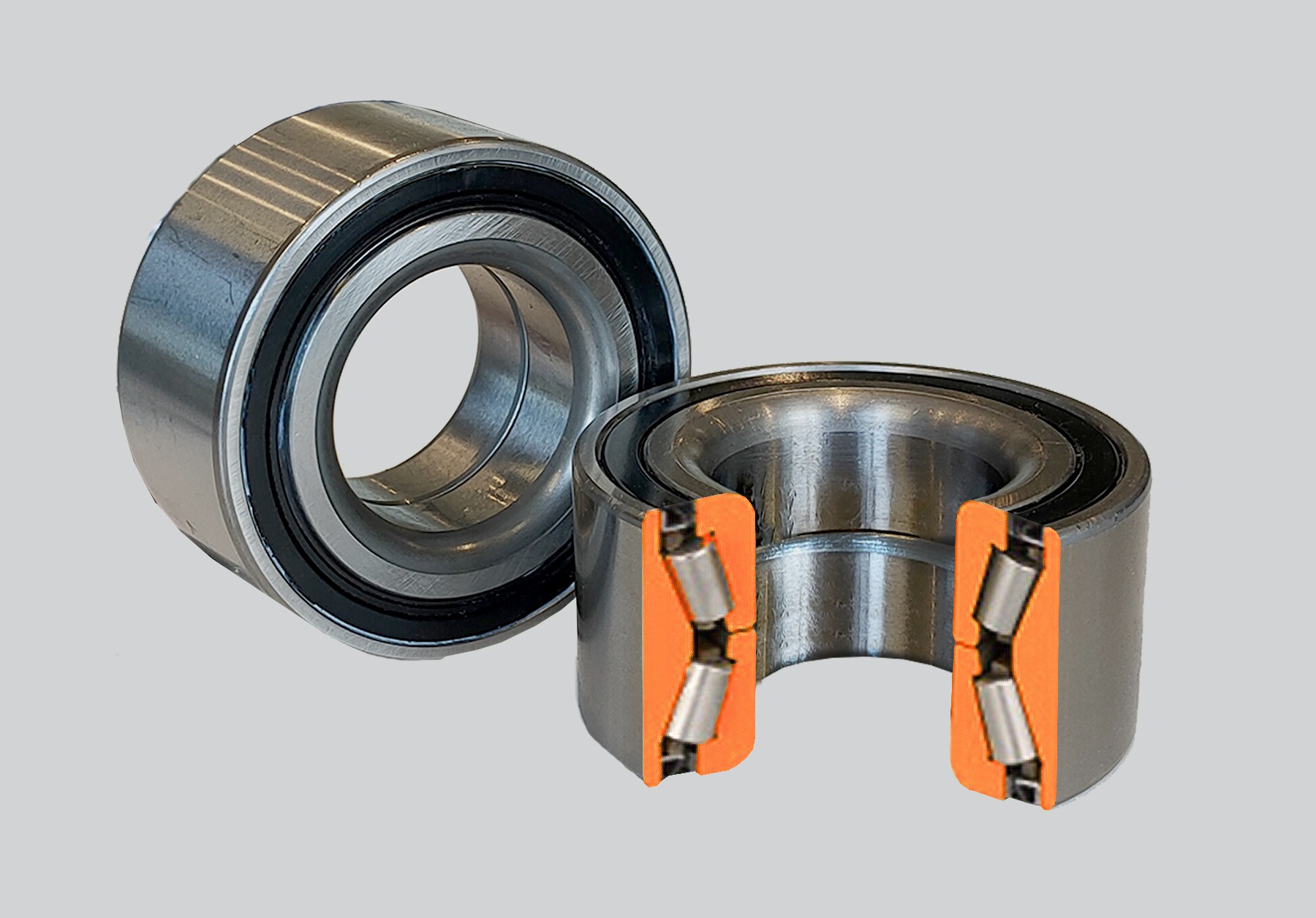

Dual row taper roller bearings - 3000kg

The two rows are angled towards the centre of the bearing in the same way as the 1.8T one, but use taper roller bearings instead of spherical ball bearings.

These have the same benefits as dual row angular contact bearings, but can carry higher loads, resist twisting even better, and are more stable under those loads.

SUPERIOR SECONDARY SEALS

The Unihub range was designed to be the best a trailer hub could be. So whilst all Unihub bearings have an integrated seal - and that vehicle manufacturers fit them just as they are - we went a step further. Trailparts have developed a completely new secondary seal arrangement on both sides of the hub to eliminate dust and water ingress.

Dust Cap - O-Ring Seal

We engineered an all-new grease cap, so that we could integrate a secondary O-Ring seal. This important feature keeps contaminants out. It also makes fitting and replacing easy as they do not risk damage during removal. These new threaded caps are less prone to being knocked off during use than the pressed steel caps commonly found on trailers.

Marine Seal - Triple-Lip

Marine seals are already widely used on trailers. We have re-engineered these to fit internally, while still having the triple-lipped characteristics that make them so good at resisting the ingress of contaminants.

These seals resist the ingress of water, meaning they are the perfect choice for boat trailers.

MARKETPLACE WHEELS

Unit bearing design requires that hub and rims be engineered to be used together. An early decision we made was to design the Unihub range around the trailer wheels that are common in the NZ marketplace.

These are very cost-effective and widely available, and also means trailers can re-use these wheels when upgrading to Unihub. This is in contrast to EU/UK trailers and components, which use notoriously expensive wheels that are not easy to locate at short notice, when you need them.

For those looking for ways to make their trailer stand out... Trailparts own, high strength ‘Kantana’ alloy wheel design has been tweaked, allowing it to fit the spigot size used with Unihub. Available in 3 colour styles.

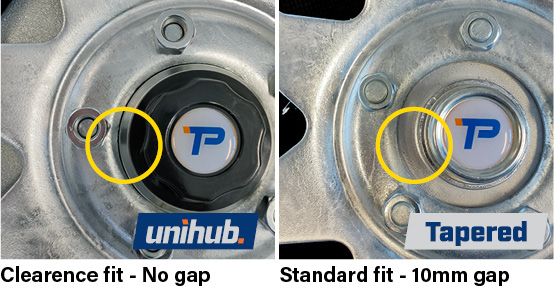

SPIGOT FIT

Wheels and hubs are always spigot mounted in automotive applications. However, the organic way trailer hub and wheel combinations have become mainstream, meant this important safety feature has been ignored.

The Unihub range introduces this feature, which is designed to eliminate improperly mounted wheels, helping prevent damage to wheel studs and nuts during fitting. Often this damage will lead to early failure in severe conditions. Unihub 1800kg center bore 81.4mm, 3500kg center bore 106.7mm.

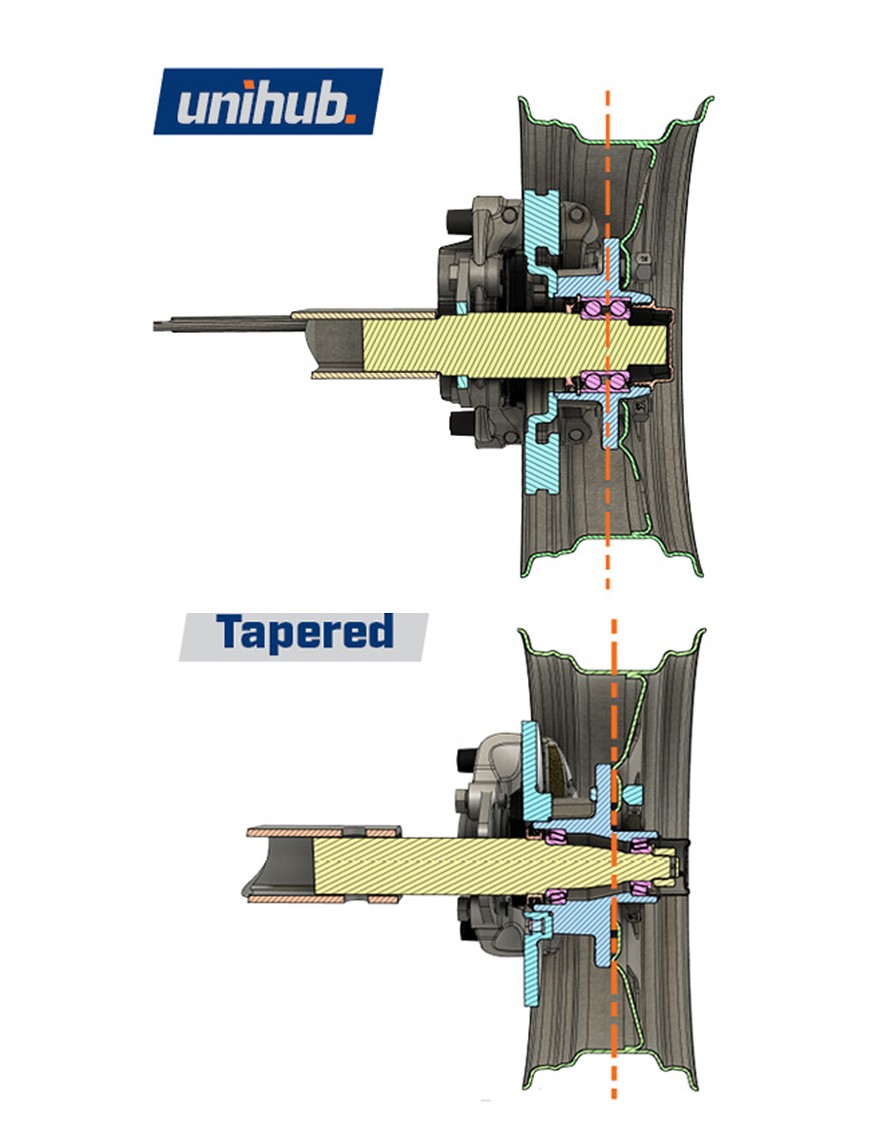

OPTIMIZED DESIGN - Better safety margins

Current common trailer hub designs with taper roller bearings were never originally designed to be used with the centred style rims they are commonly paired with. They disproportionately load the smaller outer bearing with 65% on the axial load, which can (and often does) lead to bearing failure. Along with this, the stub axles see loads further out the shaft where they are far narrower/weaker, which can (and often does) lead to bent and/or broken stub axles.

By contrast, Unihub’s entire wheel-end design (wheel, hub, stub axle and bearing) is optimized to ensure that axial and radial loads are always carried exactly where you want it to be - directly through the bearing centre, on the meaty part of the stub axle.

These shorter and thicker shafts with an engineering-led approach means safety margins with Unihub are massively increased - the 1.8T combination having a peak load safety factor of 4.8x, and 5.6x on the 3.0T hub. The Unihub is able to withstand bending loads for far longer.

UNIHUB COMPATIBILITY

Unihub has been made compatible with all of the below trailer configurations. Light or Heavy, Drum, Disc or Non-braked. Trailparts have the gear to get you on the road.

The Unihub range comprises these combinations;

- 1.8T vented disc with Patriot calipers

- 1.8T disc with STRIKE! calipers

- 1.8T 10" electric drum

- 1.8T 10" hydraulic drum

- 3.0T vented disc with Patriot calipers

- 3.0T 12" electric drum

Note: All hubs rated in pairs ie per axle