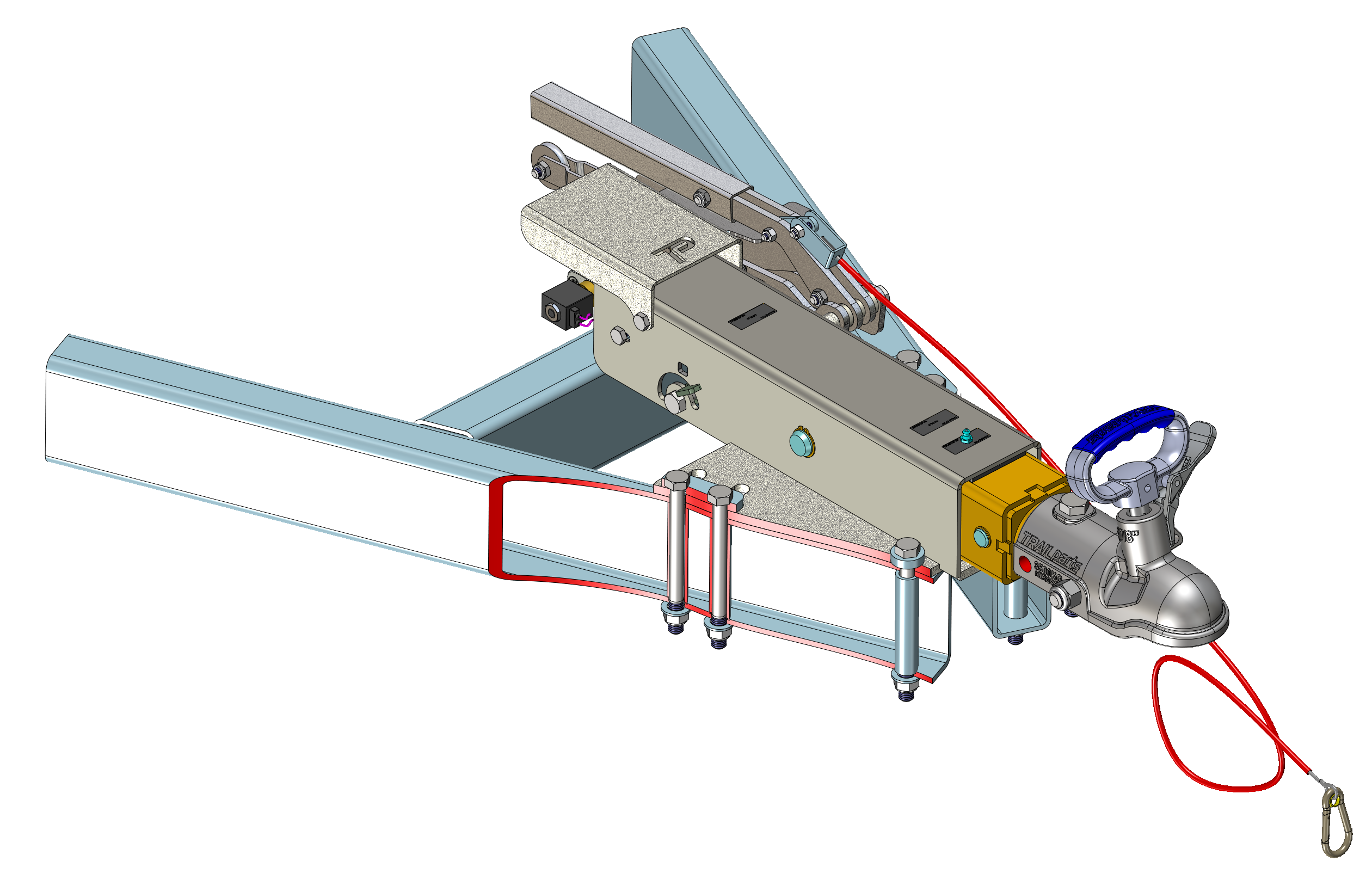

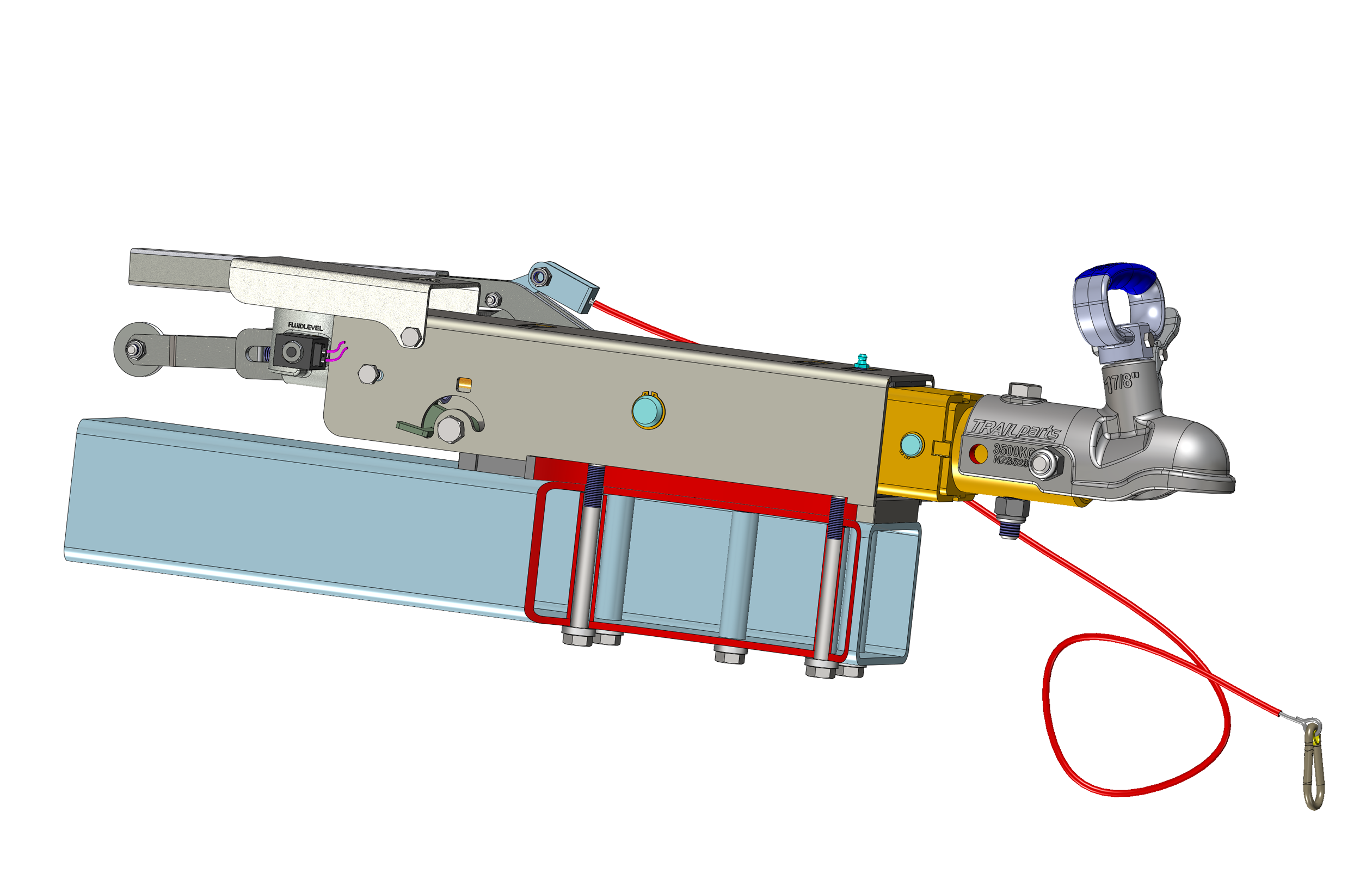

Coupling Mounting

The coupling is a critical safety item, and one of the mounting options below must be followed completely. For mount diagrams see Hygo Techincal Data

For A-Frame Drawbars

The Hygo MkII coupling can be used as a structural member, and bolted directly to the top of the drawbar as shown in diagram 1 (shown above).

- Drill the hole pattern through the top and bottom of the drawbar. The front hole centres must be at least 25mm from the front edge of the drawbar.

- Bolt through the coupling plate, and through the drawbar section.

- A bracing member must be used between the two drawbar beams. This should be a SHS or RHS profile, and cover the drawbar depth completely. This should be welded somewhere within the coupling length.

- Crush tubes that are a neat ID fit must be used inside the drawbar tube.

- Grade 8.8 or higher M12 bolts must be used in all 6 x mounting holes. These should be torqued to 130Nm.

- Plate washers >6mm must be used under the bolt heads in the four rear slotted coupling mount holes.

NOTE: A welded mounting plate can be added to this mount option if desired.

For Straight Drawbars

The Hygo MkII coupling can be used as a structural member, and bolted directly to the top of the drawbar as shown in diagram 1 (shown above).

- Trailparts will supply a different coupling mount system for this mounting style, where the coupling has a heavy 16mm plate with threaded holes designed to take bolts from underneath. The coupling mount hole pattern is the same as in common cast braked marketplace couplings – 54mm wide x 184mm.

NOTE: It is critical that every mounting step below is followed closely.

NOTE: These instructions relate to 100mm deep drawbars. Fitting to other sizes is permitted, but bolt lengths

and considerations about mounting thread engagement need to be considered. - Drill the hole pattern through the top and bottom of the drawbar. The front hole centres must be 25mm from the front edge of the drawbar.

- In this mount configuration, ½” bolts and crush tubes must be used, as they are the same thread, required to engage the pre-tapped coupling mount holes.

- Assemble the bolts and crush tubes through the drawbar, then thread into the relevant coupling mount hole.

- Tighten the ½” bolts into the coupling using a torque wrench set to 130Nm

NOTE: Trailparts stock components to facilitate this mounting as follows;

- Laser cut 6mm dual-hole washer plate for rear slotted holes.

Apply for an Exemption / Certification

Present the trailer for testing at an NZTA approved entry certifier, who will issue a VIN number, a VIN plate, and affix it to the trailer. Alternatively (Trailparts recommended) you can apply for a WMI online then contact your Trailparts for a free VIN plate.

As a part of the VIRM (Vehicle Inspection Requirements Manual), the entry certifier will want to see copies of proof that the braking system fitted to the trailer is suitable for the load being carried. The below process with walk you though the exemption application including the one-off fee of $184 and a copy of the bank confirmation;

03-0584-0007766-00

Account name: NZ Transport Agency

Bank: Westpac

Particulars: Last six digits of the vehicle’s VIN: XXXXXX

Code: CA11

Reference: Applicant Surname: XXXXXXXXXX

Email the below template to: exemptions@nzta.govt.nz

To whom it may concern,

See the attached exemption application for a trailer we have here that needs to get a WOF and be rated to 3500kg.

I’ve attached photos also showing the affixed VIN number, tyre size and the coupling for your reference also. Lastly, we have made the payment which is shown with the attached confirmation.

If you can please process this as soon as possible would be much appreciated.

Let me know any questions you may have.

Attach the follow documentation;

- Copy of the bank confirmation ($184 fee)

- Engineer's Statement with your own letter head (Sample)

- Performance Equivalence Certificate (Notice of Conformity: Trailparts Supplied)

- NZTA Exemption Application Form (CA11)

- Photo evidence: Coupling info plate, VIN Plate, Tyre - showing size, Brake cable setup - emphasis on spring.

Notes:

- Approved entry certifiers are selected branches of the Automobile Association (AA), Vehicle Inspection NZ (VINZ), Vehicle Testing NZ (VTNZ), and Drivesure Vehicle Testing Ltd.

- For manufacturers building a number of trailers, it is suggested that they apply for a WMI (World Manufacturer Identifier) that lets them issue their own VIN numbers. This will streamline the VIN application process, particularly in remote locations where no approved VIN issuer is present.