Wheel Rim Specifications

As in many industries throughout New Zealand, a strong DIY ethic exists among trailer builders and end users, and this often leads to enquiries regarding the suitability of currently available new trailer rims to replace old car rims that were commonly used to build trailers in earlier years. Rims that were used on many early model trailers, such as those from Cortina, are no longer available, and the guidelines below are intended to help explain the key criteria that will mean whether a rim can be easily replaced or not.

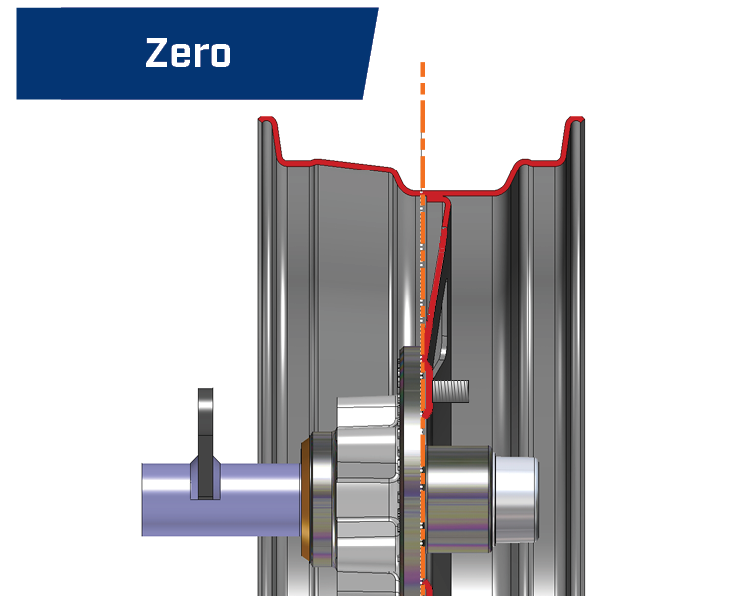

Wheel Offsets

Wheel offset is the measure used to determine where the hub mounting face is located in relation to the centre of the rim. A mounting face in the centre of the rim is known as “zero offset”; a mounting face moved towards the outside of the rim as “positive offset”; and conversely, moved towards the inside of the rim as “negative offset”. For example, a common car rim, as shown at right, has a mounting face set 35mm towards the outside of the rim, and this is expressed as “+35” or “P35”. Replacing positive offset rims with zero offset ones is possible, depending on the difference between the two, but care needs to be taken, as the way that hubs, axles and bearings carry load alters with changes in offset.

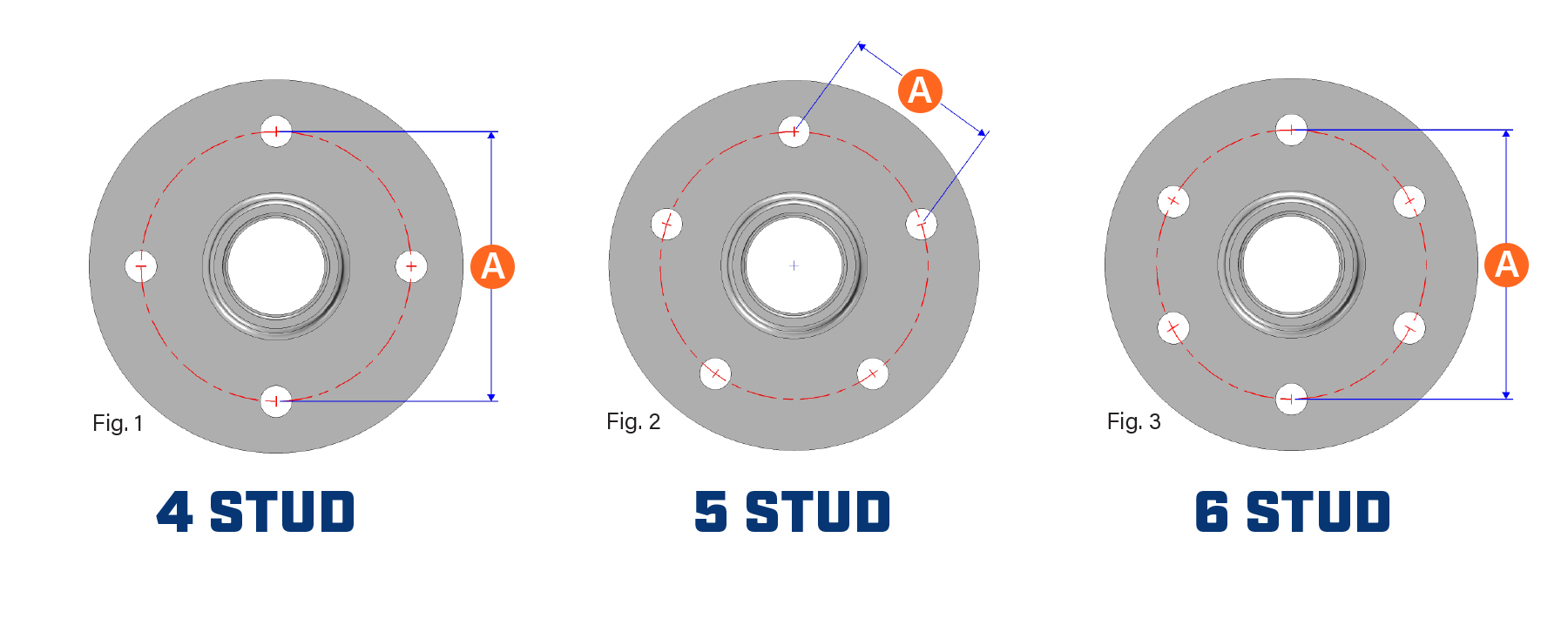

Finding a PCD Accurately

As the illustrations show below, 4 stud and 6 stud PCD’s are easy to find taking a measurement across opposite holes, but care must be taken when measuring for a 5 stud one, which can be done accurately by taking the measurement “A” in Fig.2, and divide by 0.587785. This measurement should be taken as accurately as possible, and not rounded.

PCD Calculator

- 5 Stud

Type 'A' value in the field below to calculate your PCD in Inches:

Note: Round final PCD calculation to nearest quarter inch

| PCD Inches: |

Common Stud Patterns

| No. Studs | PCD Inches | PCD Metric |

Stud to Stud |

Type |

|---|---|---|---|---|

| 4 | 4" | 101.6mm | 71.84mm | MIni |

| 4 | 4¼" | 108mm | 76.33mm | Escort/Cortina |

| 4 | 4½" | 114.3mm | 80.82mm | Most Japanese |

| 4 | 4¾" | 120.65mm | 85.31mm | |

| 5 | 4¼" | 108mm | 63.45mm | HT Holden |

| 5 | 4½" | 114.3mm | 67.18mm | Falcon/Toyota |

| 5 | 4¾" | 120.65mm | 70.92mm | Holden HQ |

| 5 | 5" | 127mm | 74.65mm | Delta Alloy |

| 5 | 140mm | 82.29mm | Ag | |

| 6 | 5½" | 139.7mm | 68.85mm | Landcruiser |

Wheel Nut Torque Settings

A quality torque wrench should always be used to tighten wheel nuts according to the values shown in the table. This ensures a safe connection and avoids dangerous damage to wheels, studs and nuts from under or over tightening. Wheelnuts should always be re-torqued again after having travelled 200km.

| Thread | Torque |

|---|---|

| M12 | 80ft/lb or 108Nm |

| 7 ⁄ 16” UNF | 80ft/lb or 108Nm |

| 1 / 2” UNF | 90ft/lb or 125Nm |